1990s

New Mills, Braintree

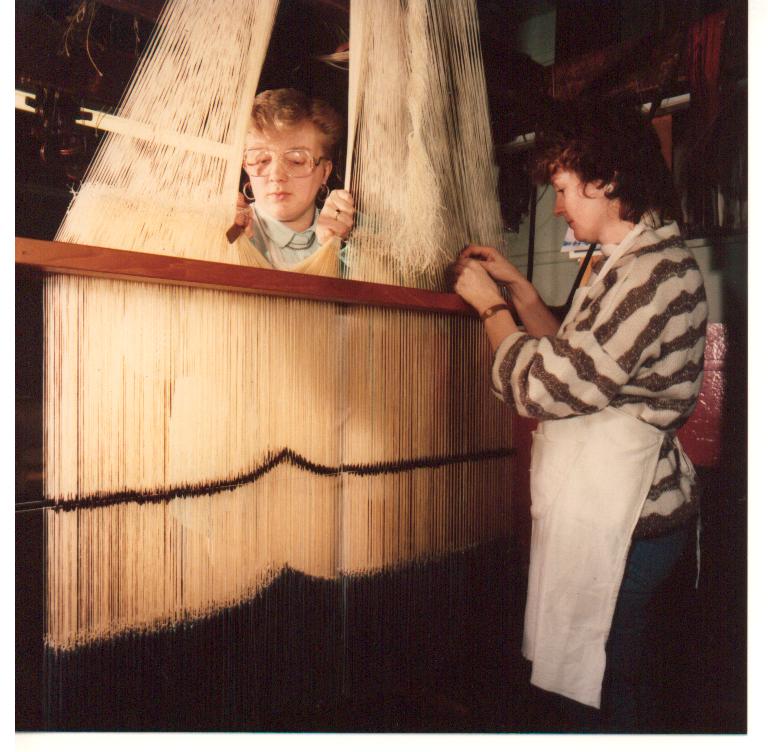

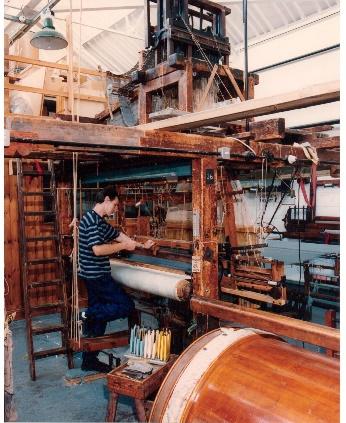

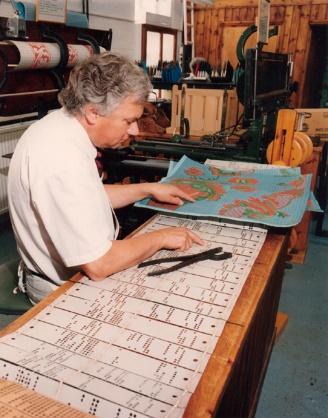

The weaving company had 18 month’s work booked in advance and the museum received 70,000 visitors in the first 12 months. This also meant an up-turn in staff levels rising to 23 employees. With ten looms at New Mills and a further six at DeVere Mill the variety of cloths available gave the business a leading edge in custom cloth for decorators and designers. There was space at DeVere mill to build a new dye house for specialist colours.

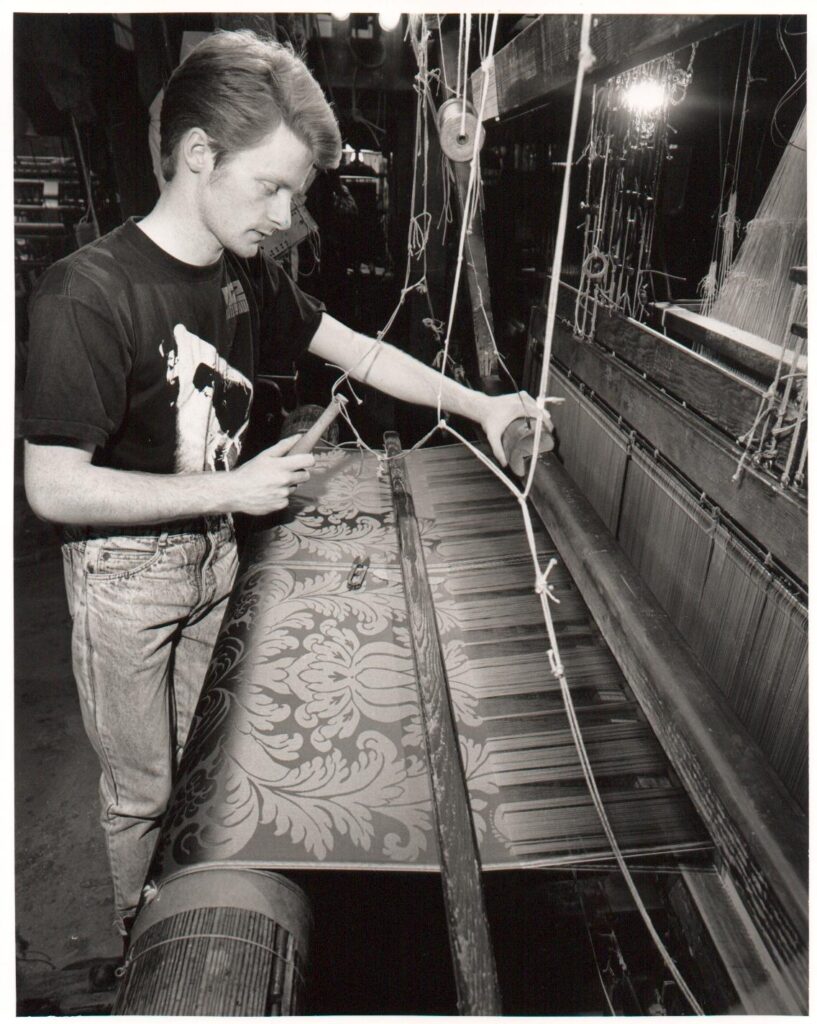

In 1992 another devastating Royal Palace fire took place at Windsor Castle where Richard had already spent years reweaving damask for several rooms. Again, Humphries Weaving used their archive and access to the palace team to research and recreate multiple bespoke fabrics for the restoration of the State Apartments.

Alongside this body of work historic recreation commissions were received for Spencer House, Kensington Palace, Apsley House and Kedleston Hall and London wholesalers were taken on in order to relieve pressure on decorator cloth sales allowing Richard to concentrate more on the making of historic fabrics required.

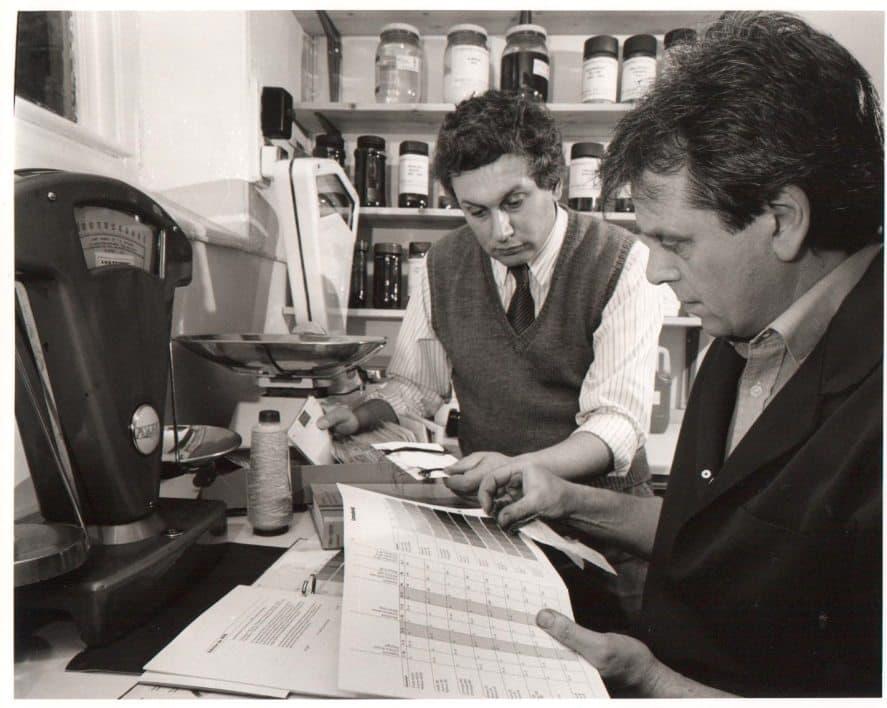

The volume of business led to developing a silk throwstering floor at DeVere Mill to give a vertical manufacturing ability from raw silk to made-up product for retail. This activity was requiring attention on the two sites which were nine miles apart so there was a daily delivery from one to the other which included transport for employees. By the mid-1990 the business was really at a very critical point where both sides of the business of tourism and fabric manufacturing were at full capacity.

At this same time the silk market took a massive hit when China lowered its prices so low as to render all throwstering in the UK a non-viable activity. When the price reached half of what it was, this meant the end of the making of silk thread for Richard and with his lease up for revision at New Mills it was time to condense the activity into DeVere mill once more.