Sudbury Silk Tales – A Hand Weaver Tells the Story

The Suffolk town of Sudbury, bordering the Essex County, has a weaving tradition dating back centuries. Humphries Weaving is a relative new comer to Sudbury starting in 1972 after the closure of Warner & Sons New Mills at Braintree, Essex. What had been a wool trade town, by the end of the 18th Century Sudbury had given way to the processing and manufacturing of silk. The declaration of the Spitalfields Act in the 1790’s had forced manufacturers of silk in the east-end of London to consider moving away to evade the law and it’s consequences. Towns on the Essex Suffolk border such as Braintree, Halstead and Sudbury found themselves outside the scope of the Act. Sudbury being positioned on the navigable river Stour, which offered a transport passage to the Thames estuary and the Port of London for export to the Americas, in addition to its weaving heritage, meant that it was an ideal place for this industry to flourish.

Long before any thought of weaving cloth in the mill, textiles were woven on hand looms in workers dwellings alongside everyday life. This enabled most to survive but for some there was a chance to prosper. Silk is not a natural product of our country and whilst King James I dearly wished for sericulture as an industry to succeed in his life time, it was not to be. Silk had to be purchased from far flung places such as China and be imported through the major city ports. The processing of silk thread is a complex business and the purchasing of raw silk import is just the beginning. Throwing, twisting, winding, reeling and warping are some of the many pre-weaving processes required.

Thomas Lombe was credited with being the first to throw silk in England, having spent time in Italy, where he was able acquire the necessary knowledge of this highly secretive process. Throwing was just one of the many branches of trade needed to prepare the thread, in readiness for the weaver to make the cloth. Therefore, the arrival of the Silk Trade in towns, such as Sudbury, brought prosperity, income and skills to the region and a skill set that has continued to develop over the last two hundred years. Weavers and their masters were facing hardship in Spitalfields where the high costs of manufacturing rendered the production of silk, in this part of east London, no longer viable. Hard pressed weavers walked from Spitalfields to the Essex Suffolk border to seek employment whilst their masters with un-lettable cottages in Bethnal Green faced certain bankruptcy if they remained there with no tenants.

The Walters family, with other familiar names such as Charles Norris, John Vanner, Keith and Co, Bailey, Fox & Co. and Stone and Kemp, were at this time weavers manufacturing in Spitalfields. To make cloths free of the Spitalfields tax, families of weavers made their way to Sudbury and other East Anglian towns to start anew. The cottage system providing both shelter and a workshop.

Master weavers built tall three-story town houses for Journeyman weavers to rent, live in and set to with their looms. Loom rents however would be collected from the weavers without their own equipment, with master’s allowing a weekly payment drawn against the job undertaken. Weavers were generally allowed to draw on a job value as soon as they started. With many in debt from previous shortfalls in income, the system was open to much abuse as foremen could favour some weavers against others for purely financial gain. This pay system was much in operation at Daniel Walters & Sons at “New Hall” North Street Sudbury. Benjamin Warner retained the cottage velvet weavers at Sudbury, whilst their main operation was centred at “New Mills” South Street Braintree. By the early 20th Century it was said that Warner weavers were so far behind in paying their shortcomings that much hardship was caused. Eventually an amnesty had to be declared with the sudden dismissal of the works foreman, and the wiping out of all moneys owed.

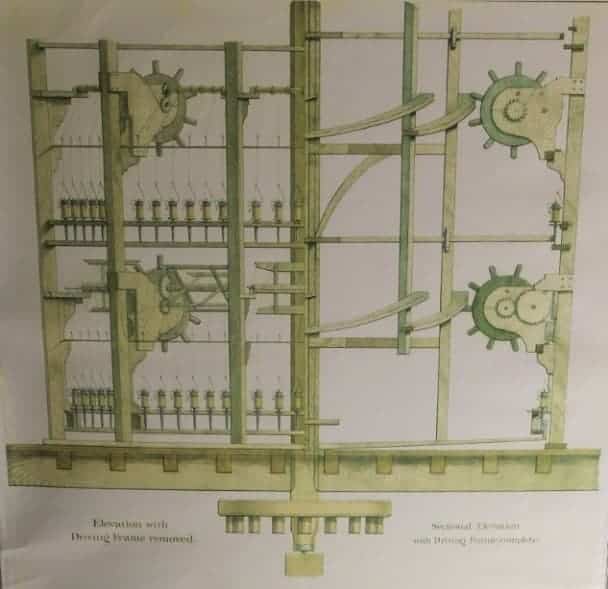

Whilst Charles Norris established a works on the Melford Road overlooking the Water Meadows, other family firms made their move to Sudbury to set up weaving in other parts of the town. Stone and Kemp of Spital Square in Spitalfields came to Sudbury sometime in the middle of the 19th Century with George Taurke Kemp heading the business. They built a silk throwing mill to the rear of his Cross-Street weavers’ cottages. The water powered mill was driven by a race constructed to the rear of Cross Street. In 1851 he was made Upper Bailiff of the London city livery, the Worshipful Company of Weavers. This position was later taken up, in 1861, by John Vanner. This was a prestigious position that would prove too costly for Kemp, as a year later he was declared bankrupt. His sons took on the business as Thomas Kemp & Co and they were still weaving silk in Sudbury in 1911.

During this time, umbrella silk was the mainstay of production for some firms in the town, along with plain velvet weaving for furnishings. Velvet making continued until the invention of a new German power-loom which wove two velvets face -to- face. This undermined the hand weavers’ price considerably. The cost became so competitive that, except for Royal patronage, by the 1890’s the trade was all but lost. Warner & Sons took over the works of Charles Norris, whilst Bailey Fox and Co continued velvet weaving in Sudbury. Both Warner & Sons and Bailey and Fox made silk velvets for the Coronation of Edward VII.

The largest of the silk firms was that of Daniel Walters & Sons, who continued to weave the finest of silk furnishings at both New Mills Braintree and Sudbury and it is said to have employed 300 hands. But in 1895 Daniel Walters was facing bankruptcy and he entered a year of negotiation with Benjamin Warner, hoping that he would take on the business. Warner did this in 1896 and began to move his production from Spitalfields to Braintree and Sudbury.

Many weavers were facing such hardship that they were unable to afford the train fares to these towns and so chose to walk from London. Such was the good spirit of these weavers that it was said that much merriment was had along the way with hospitality being freely given as the party made its journey. The occasion was commemorated for a number of years, with a competitive walk, from Bethnal Green Road to New Mills Braintree in Essex, organized by the Silk Weavers of Warner & Sons.

Whilst Daniel operated from “New Hall” in North Street Sudbury his brothers firm Stephen Walters which was kept separate, operated in Kettering and Haverhill and by the 1860’s in Acton Square in Sudbury. The Walters family can trace their beginnings back to 1720 when Benjamin Walters began his involvement with the silk trade. In Haverhill, Walters are recorded as erecting a silk mill as early as 1828. The coming of the railway in 1865 to Sudbury, enabled Stephen Walters to keep Haverhill journeyman weavers supplied with silk canes (warps on beams) from Sudbury. In turn, rolls of woven Umbrella silks, woven in Haverhill, were returned by train to Sudbury. The system was said to have been a great success with the station porters taking charge of the distribution and collection at either end.

At the end of the 19th Century Stephen Walters moved to the newly built Sudbury Silk Mills on the Cornard Road. The Mill was built by Kipling & Company who was a silk cravat manufacturer also in Haverhill but they were declared bankrupt before they could take possession of the building. Stephen Walters were at that time operating in Girling Street Sudbury, prior to their move to Cornard Road.

When Humphries Weaving started in 1972 it began production on the same ancient hand looms saved from Daniel Walters and Warner’s at New Mills. Starting up in Ashburton Lodge the early beginnings of their manufacturing included hand- cut velvet weaving for the Garter Robe for the Prince of Wales and pure silk Lustring’s for the interiors of Hampton Court Palace. Since those early days Humphries has continued a journey of both restoration of the past in exquisite silk furnishing for the most luxurious period interiors but also new and modern textiles for today’s top interior decorators.

Article by Richard Humphries MBE FRSA September 2019