Textile Fibres

The journey from humble yarns to royal fabrics

Yarn is defined as the continuous length of interlocked fibres used for the production of woven or knitted fabrics, for sewing and for embroidery. The many different characteristics offered by these textile fibres enables us to produce a large range of luxury fabrics. Our state of the art looms are able to adapt to weaving the finest silk damasks one day, and heavy weight cotton chenilles for transport restoration the next.

A small selection of our woven fabrics, ranging from plain lustring to figured damasks using a variety of complex weave constructions.

We use our knowledge of each yarn to design and to create fabrics for a range of end uses. This is something that we consider carefully throughout the woven fabric design and development process. There are a multitude of characteristics to balance that include luster, weight, texture and performance. Creating fabrics using a combination of different yarns requires the choice of textile fibres that compliment each other, however the perfect balance can also be achieved through creative technical designing. Our half silks (a popular fabric using a combination of silk & wool), are a perfect example of where we utilise two very different yarns to create a beautiful contrast of matt against shine.

Yarns can be categorised into three distinct groups:

Protein yarns are created using fibre derived from animals and insects. The most widely used examples include silk and wool.

Vegetable or plant-based fibres are often referred to as cellulose yarns. These include cotton, linen, flax and viscose. However, viscose is a man-made fibre produced from wood pulp.

Synthetic fibres. These are man-made yarns with the most well known being polyester.

A selection of colourful silks about to be woven into fabric.

Silk

Humphries Weaving is based in Sudbury, England. Sudbury has a rich weaving history and the towns industry imports over 150 metric tones of silk each year. This is more than any other town in the UK. Silk is natures only continuous filament yarn, with our silk extracted from the cocoons of the Bombyx Mori silk worms. This practice is commonly known as “sericulture” and the skills required for this process take over 20 years to perfect.

The silk cocoons are soaked in hot water before the silk is unwound to obtain the continuous filament. Usually each cocoon supplies around 1km of thread which is formed of two fibres glued together with a natural gum produced by the silk worm. Eight to twelve of these are combined or twisted together to create a usable yarn that is called a “single”. Multiple singles are then twisted together to form the warp and weft yarn we use for our fabrics.

Silk worms & cocoons at a working Silk Museum

The most appealing characteristic of silk is its shimmering appearance. This is due to the triangular prism-like structure of the silk fibre, which allows silk cloth to refract incoming light at different angles, thus producing complex and rich colours. It also has a wonderful drape and has justly gained its reputation as the “luxury fibre”. This is due to the yarns high value and complex production methods.

Frequently used for the weaving of pure silk damasks and plain cloths like satins, lutes and lustrings, it is the typical choice of royal residence and prestigious interiors. Historically, trends saw the same design and colours featuring throughout a scheme, and therefore the same fabric can often be found applied to window drapes, upholstery and wall coverings. For more examples of our sumptuous silks click here.

Our rich silk tissue used for the restoration of The Saloon, The Brighton Pavilion. © Jim Holden/Royal Pavilion & Museums

Wool

Historically England has been famous for producing wool due to our ideal climate and land suitable for sheep farming. For hundreds of years the wool industry was the financial backbone of East Anglia. Wool was king until the middle to late seventeenth century when silk became the more fashionable. The wool weavers of Norwich then had to adapt and the city soon became the centre for ‘half-silks’ . These are fabrics made from a combination of silk and other fibres, which produces a beautiful contrast between matt and shine. For more information about these fabrics read our “Half Silks” article here.

Left: Blue Silk/ Cotton Half Silk Stambourne Basket Damask woven by Humphries Weaving in 2008 for Morris-Jumel Mansion Right: Crimson Silk/Wool Half Silk New Pavia woven by Humphries Weaving in 2008 for Gunston Hall Virginia.

Humphries to this day still weave many half silks. However we also produce 100% wool fabrics in the form of tammies, camlets, wool damasks and many more.

Wool can be sourced from many different breeds of sheep. The fleece is sheared before it is cleaned in a process called “scouring,” (this refers to the removal of impurities within the fibre.) Once clean the fibres are then carded ,(or combed,) and then the short staple length fibres are spun together to produce a usable yarn.

Wool yarns are produced in two main categories: Worsted and Woollens. We mainly use worsted spun yarn – weaving cloth from yarn of longer staple wool that has been combed and stretched under tension to create a higher twist. As a result, the appearance is much smoother, drapes well and has a slightly more lustrous quality. Woollen spun yarns make up the second category and have the opposite appearance to worsted yarn. Woollen yarns contain shorter staples which are carded so that the fibres sit across each other. This creates a much more textured finish. Because these yarns contain lots of air, they are light and fluffy which makes them more suitable for knitted textiles.

Cotton & Linen

Cottons and linens make up our plant based yarn offer. These are the yarns used more often by leading interiors brands as they are ideal for heavy weight upholstery. Cotton is harvested from the lint that surrounds the seed cases of the cotton plant. The production of cotton follows a similar combing and spinning process to that of wool. The resultant yarn has a slightly hairy texture which can be reduced by a process called gassing that removes the most prominent textile fibres. This produces a yarn suitable for fine furnishing fabrics.

Linen is formed from the cellulose fibres that grow inside of the stem the flax plant, one of the oldest cultivated plants in human history. Once harvested the long strands are separated using water or chemicals, before they are spun into the longer lengths of yarn. These longer textile fibres are responsible for the durability of the cloth, which also has insulating properties keeping you warm in winter and cool in summer.

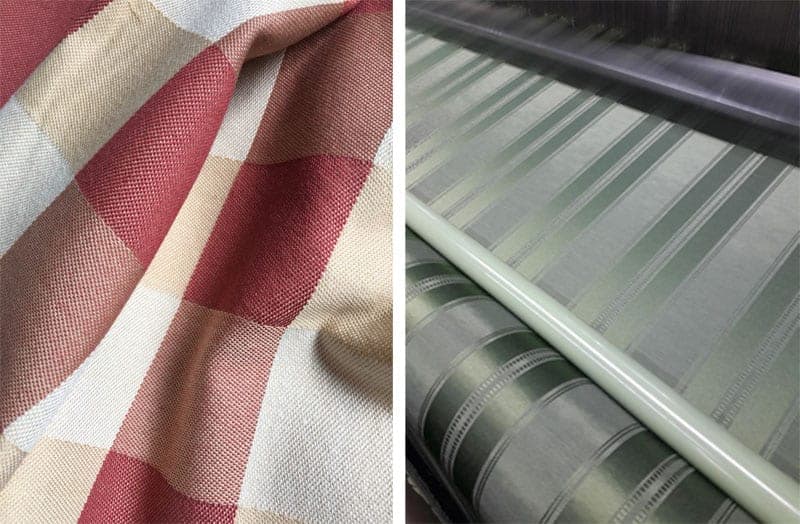

Cotton & Linen create a matt aesthetic to the cloth which retains a drape and the added property of durability. As well as being the go-to choice for modern interiors it can also be used alongside silk to create a mixed composition historic textile, as seen in the taboret stripe below:

100% stock cotton gingham Custom Silk & Linen taboret stripe

Fine viscose

Viscose is a man-made fibre containing many similar qualities to those of silk. It is made from wood pulp which is extruded through a tiny hole to create a continuous filament yarn. It offers the same lustre and drape as silk but being made from a single filament it is much less effected by abrasion and offers a high performance alternative to silk. For further details read our article on fine viscose click here.

Colour trials using fine viscose weft, offering a similar aesthetic to a 100% silk fabric.

Other novelty yarns

Humphries Weaving also offer our clients a selection of novelty yarns to chose from. These include Cotton Chenille’s, Lumi, Lurex, Silk Noile and Bourette yarns. These are available in a variety of colours; however, we also offer custom dying for colour matching to meet our clients exacting requirements.

Silk, cotton and metallic lumi yarn tissue fabric for chasubles at St Marys Iffley